785D Bare Chassis

785D Off-highway Truck Bare Chassis

Caterpillar offers partial machines and systems, working with Cat® dealers and Original Equipment Manufacturers (OEMs) to provide specialty machines for specific applications. Bare chassis trucks can be ordered with or without hoist cylinders and most product options are identical to the dump truck models. These models come equipped with a higher Tractor ROPS certification needed for specialty machines including water trucks, tow trucks, and fuel / lube trucks. These partial machine configurations are used in construction, demolition, waste, material, handling, quarry, and mining applications.

The Cat Water Delivery System (WDS) is available as an optional attachment on the 785D WTR Off-Highway Truck Bare Chassis. This includes factory installed controls in the cab, a hydraulic pump and motor, a water pump, and stainless steel spray heads. Whether your goal is dust control or haul road maintenance, the Cat WDS is designed to put water to the ground in a controlled, intelligent way. The simple to operate automated system allows you to concentrate on more important safety issues like traffic, personnel, and road conditions. You’ll also find that the Cat WDS not only improves safety, it also reduces truck maintenance costs, conserves water, and provides significant fuel savings to help your bottom line.

Tractor ROPS Rating

- Cat® Off-Highway Truck Bare Chassis ROPS is certified to ISO 3471 Tractor criteria, to provide a higher level of protection for towing applications.

Water Truck Applications

- Cat Off-Highway Truck Bare Chassis are rugged and reliable platforms for water truck applications in both mining and construction projects.

- Using an off-highway truck bare chassis provides a solution that is ideal for dust suppression, road construction, fire protection, and other applications.

- Caterpillar works with OEMs worldwide to match the appropriate bare chassis machine to the water truck application, all through your local Cat dealer, to provide the best solution for your business.

Service Truck Applications

- Cat Off-Highway Truck Bare Chassis are rugged and reliable platforms for service truck applications in both mining and construction projects.

- Using an off-highway truck bare chassis provides a solution that is ideal for delivering fuel and preventive maintenance lubrication to your site's machine fleet.

- Caterpillar works with OEMs worldwide to match the appropriate bare chassis machine to the service truck application, all through your local Cat dealer, to provide the best solution for your business.

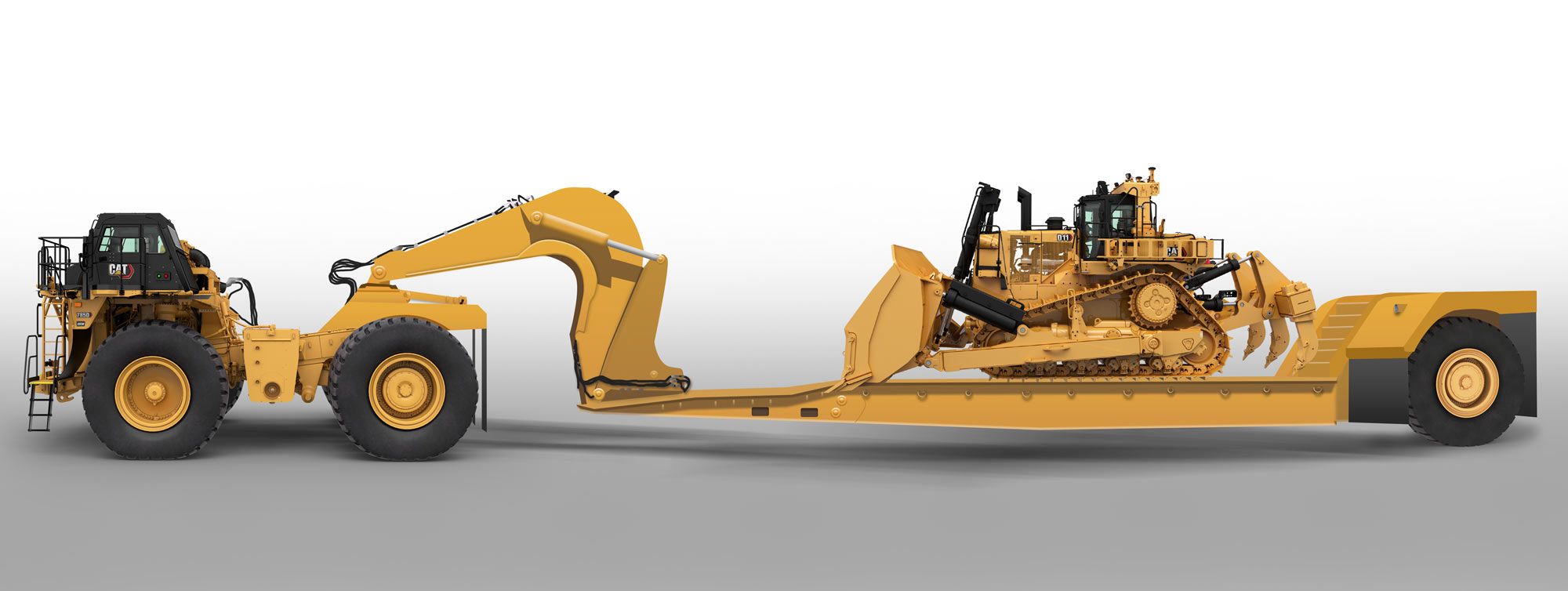

Tow Applications

- Cat Off-Highway Truck Bare Chassis are rugged and reliable platforms for tow applications.

- Using an off-highway truck bare chassis provides a solution that is ideal for equipment trailers and bottom dump trailers.

- Caterpillar works with OEMs worldwide to match the appropriate bare chassis machine to the tow application, all through your local Cat dealer, to provide the best solution for your business.

فيديو

جولات افتراضية

المستندات والكتيبات

المعدات القياسية

For bare chassis standard and optional equipment, please reference the 785D Off-Highway Truck. For more information on 785D Bare Chassis options, please contact Caterpillar OEM Solutions at [email protected].

POWERTRAIN

- Cat 3512C HD-EUI diesel engine: Air Cleaner with Precleaner (2) Engine, Engine Shutdown, Ether starting aid, Air to air aftercooler (ATAAC), Elevated low idle control, Auto starter protection, Multi-point oil pressure sensing, Antifreeze, extended life coolant -35° C (-30° F)

- Braking System: Brake release motor (towing), Oil-cooled, Multiple-disc (front and rear),

(service, retarding, parking, secondary), Automatic retarder control, Engine overspeed protection, Extended life brake disc - Transmission: 6-speed automatic powershift with electric control (TCC), Body-up shift inhibitor, Controlled throttle shifting, Directional shift management, Downshift/reverse shift inhibitor, Individual clutch modulation, Neutral coast inhibitor/start switch, Body-up reverse neutralizer, Programmable top gear, Lock-up torque convertor, Caterpillar flexible core radiator

ELECTRICAL

- 24V electrical system, low maintenance batteries (2) 93 amp-hour

- Alarm, Back-up

- Alternator, 105 ampere

- Batteries, 12V (2), 93 amp/hour

- Converter, 12V electrical

- Electrical system, 24V, 15 amp

- Lighting System, LED: Backup and hazard lights, Directional signals, front and rear, Headlights amd foglights, Lo-hi beam selector, Left-hand ladder/service deck, Stop/tail lights, Engine compartment, VIMS, blue light

- Payload, indicator lights

OPERATOR ENVIRONMENT

- Air Conditioner

- Coat hook

- Diagnostic connection port

- Dome courtesy light

- Entertainment radio ready: 5 amp converter, speakers, antenna, wiring harness

- Gauges/Indicators: Air cleaner service indicator, Quad gauge panel: Air pressure, Brake oil temperature, Engine coolant temperature, Fuel level, Electric engine control fault indicator, Electric hour meter/tachometer, Speedometer, Tachometer, Transmission gear indicator, VIMS message center with universal gauge, VIMS keypad, Heater/defroster

- Horn

- ROPS cab insulated/sound suppressed

- Storage compartment

- Seatbelt, 75 mm (3 in), retractable

- Steering wheel, tilt, padded, telescopic

- Sun visor

- Tinted glass

- Window, electric powered, operator

- Windshield wiper, intermittent control, and washer

OTHER EQUIPMENT

- Air Line Dryer (2)

- Body Mounting Group

- Auto lubrication system (Lincoln)

- Dumping, Auxiliary Quick Connect for "Buddy Dumping"

- Steering, Auxiliary Quick Connect for Towing

- Continuous rear axle filtration

- Diagonal stairway, 600 mm (24 in)

- Driveline Operator Safety Guard

- Fast-fill Fuel System

- VIMS Dataport

- Battery Disconnect

- High speed crankcase oil change

- Grease injector

- Reservoirs (separate): Brake/converter/hoist, Steering, Transmission

- S•O•S℠ ports

- Supplemental steering, automatic

- Tie down eyes

- Tow hooks, front/tow pin, rear

- Traction control system

- Vital Information Management System (VIMS)

- Mounting, Water with Hoist Cylinder

CAT TECHNOLOGY PRODUCTS

- Object Detection System (cameras and radar)

- Product Link Elite

معلومات إضافية

| Engine Model | Cat® 3512C HD |

|---|---|

| Rated Engine Speed | 1750 r/min ( 1750 r/min ) |

| Engine - Gross Power - SAE J1995 | 1082 kW ( 1450 hp ) |

| Engine - Rated Net Power - SAE J1349 | 1005 kW ( 1348 hp ) |

| Engine - Bore | 170 mm ( 6.7 in ) |

| Engine - Stroke | 215 mm ( 8.4 in ) |

| Engine - Displacement | 58.56 l ( 3573.6 in³ ) |

| Engine - Note | Net Power advertised is the power available at the flywheel when the engine is equipped with air intake system, exhaust system, and alternator |

| Weights - LRC Bare Chassis Weight without Hoist | 80426 kg ( 177309 lb ) |

| Weights - LRC Bare Chassis Weight with Hoist | 82022 kg ( 180827 lb ) |

| Weights - LRC Gross Vehicle Weight (Target) with Hoist | 249476 kg ( 550000 lb ) |

| Weights - LRC Gross Vehicle Weight (Target) without Hoist | 249476 kg ( 550000 lb ) |

| Operating Specifications - Nominal Water Tank Capacity | 113500 l ( 30000 gal (US) ) |

| Tractor ROPS | 94000 kg ( 207234 lb ) |

| Transmission - Forward - 1 | 12.1 km/h ( 7.5 mile/h ) |

| Transmission - Forward - 2 | 16.3 km/h ( 10.2 mile/h ) |

| Transmission - Forward - 3 | 22.2 km/h ( 13.8 mile/h ) |

| Transmission - Forward - 4 | 29.9 km/h ( 18.6 mile/h ) |

| Transmission - Forward - 5 | 40.6 km/h ( 25.2 mile/h ) |

| Transmission - Forward - 6 | 54.8 km/h ( 34 mile/h ) |

| Transmission - Reverse | 11 km/h ( 6.8 mile/h ) |

| Transmission - Note | Maximum travel speeds with standard 33.00-R51 tires. |

| Brakes - Brake Surface - Front | 61270 cm² ( 9497 in² ) |

| Brakes - Brake Surface - Rear | 89729 cm² ( 13908 in² ) |

| Service Refill Capacities - Fuel Tank Capacity | 1893 l ( 500 gal (US) ) |

| Service Refill Capacities - Cooling System | 379 l ( 100 gal (US) ) |

| Service Refill Capacities - Crankcase | 204 l ( 54 gal (US) ) |

| Service Refill Capacities - Differential - Final Drives | 436 l ( 115 gal (US) ) |

| Service Refill Capacities - Steering System - Including Tank | 641 l ( 31 gal (US) ) |

| Service Refill Capacities - Brake Hoist System | 337 l ( 89 gal (US) ) |

| Service Refill Capacities - Brake/Hoist Hydraulic Tank | 641 l ( 169 gal (US) ) |

| Service Refill Capacities - Torque Converter - Transmission System | 248 l ( 65.51 gal (US) ) |

| Steering Standards | ISO 5010:2007 |

| Steering - Steer Angle | 36 ° ( 36 ° ) |

| Steering - Turning Diameter | 29.8 m ( 97.7 ft ) |

| Steering - Turning Circle - Clearance Diameter | 33.2 m ( 109 ft ) |

| Offering Type |