D8

MAXIMIZE EFFICIENCY

- Move more material at alower cost. Proven power train and Auto Shift give you both power to the ground and fuel efficiency.

- Move up to 13 percent more material per pass with the largest standard blade in the size class (10.3 m³/13.5 yd3).

- Keep working, even in high temperatures, with high ambient cooling capability.

- Auto Shift automatically down shifts to the most efficient gear based on load for fuel savings.

- Dual Tilt option optimizes blade pitch for up to 10 percent more productivity.

Note: Comparisons to previous D8R/D8T models

BUILT TO PERFORM

- Cat C15 engine brings you more than a decade of proven reliability in a wide range of working conditions.

- Harness more power to the ground with a planetary power shift transmission and high efficiency torque divider.

- Rugged mainframe absorbs high impact shock loads and twisting forces.

- Pivot shaft design allows the machine to better follow ground contours for maximum traction and operator comfort.

- Elevated sprocket helps protect major components from harsh impacts and provides a modular design for convenient service.

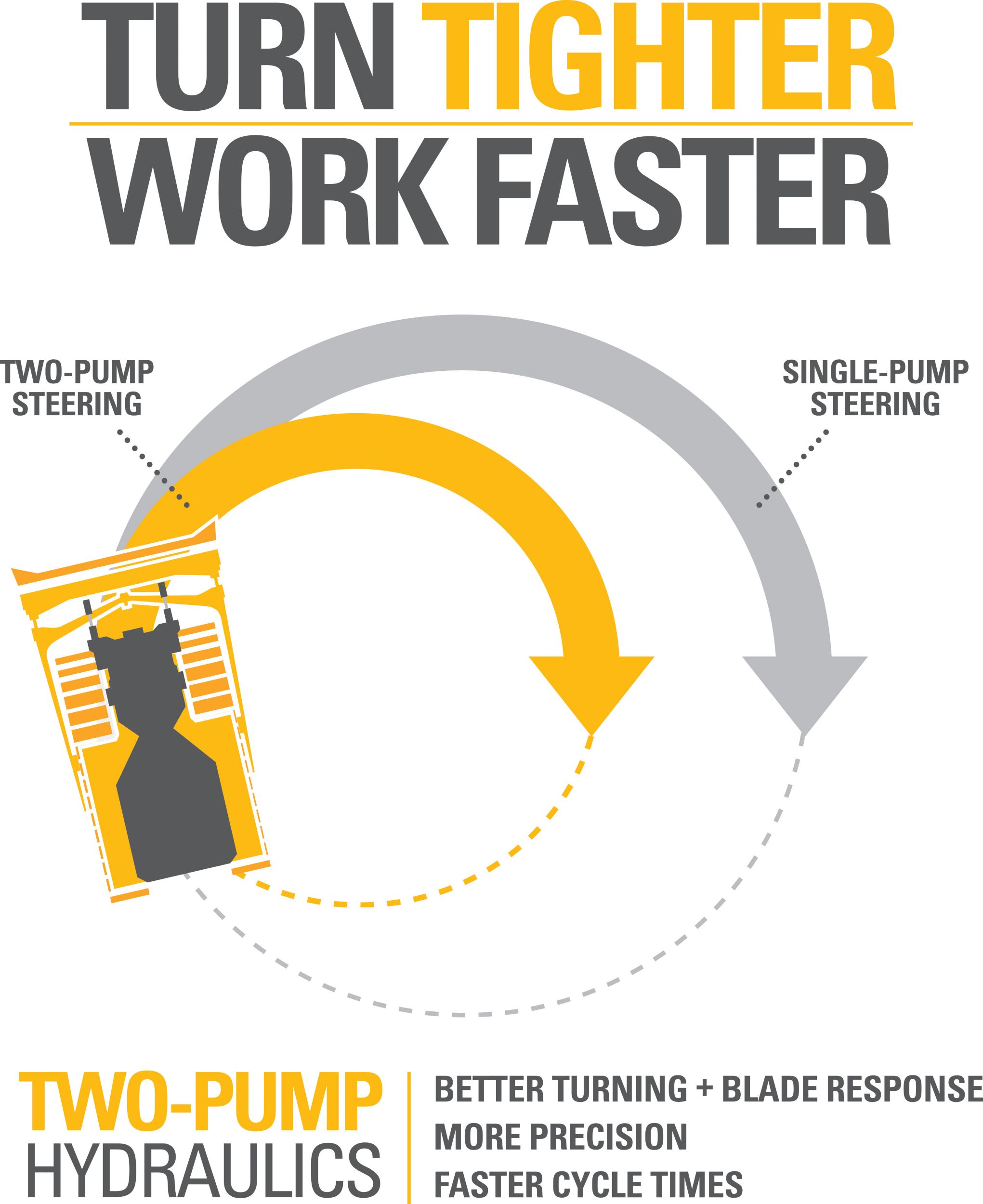

- Dedicated implement and steering pumps mean you can count on simultaneous blade response and steering performance.

- Differential steering gives you exceptional turning, even with a full blade load.

Note: Comparisons to previous D8R/D8T models

HANDLE THE DESERT HEAT

- High ambient capability makes the D8 well suited to extreme heat so you can work longer without shutting down.

- Push in second gear to work faster without overheating.

- Choose from a variety of factory options to support machine performance and service life in extremely sandy or abrasive conditions.

- Turbine precleaner prevents particles from entering the engine system.

- Solid-bottom engine enclosure doors help keep sand out forimproved cooling and reduced cleanout.

- Specially coated fan and radiator core protection help resist abrasion. Reversing function is disabled on the hydraulic demand fan.

- Sealed bottom guard and added seals help keep fine abrasive particles out of components. Access panels facilitate cleanout without removing bottom guard.

- Replaceable wear plates offer longer blade life when working inabrasive conditions.

OPERATOR COMFORT AND CONTROL

- Integrated Roll Over Protection Structure (ROPS) offers excellent all-around visibility to enhance productivity.

- Quiet interior with improved pressurization helps keep dust out.

- Standard air suspension seat is adjustable for operator comfort.

- Optional electro-hydraulic controls reduce operator effort, improve precision and response, and enable Cat Grade technologies.

- Pre-select forward/reverse gears with Bi-directional control to save effort and improve efficiency.

- Implement Lock-Out prevents inadvertent operation of hydraulic attachments.

- Liquid Crystal Display (LCD) places machine data, settings menus, grade control data and more conveniently in front of the operator.

- LCD display is rear-camera-ready for added safety.

BECAUSE UPTIME COUNTS

- Cat dozers are designed with features like wide engine panel access doors to minimize maintenance and repair time.

- Exclusive new Cat hydraulic and power train oil filters offer extended service intervals to save you time and money.

- Ecology drains help reduce spills during power train fluid changes.

- Fast fuel system at ground level, with positive fuel shut-off, helps prevent fuel spillage/waste and speeds refueling for more uptime.

- High-speed oil change attachment to help make servicing even faster.

- Cab-mounted air conditioning condenser supports better system performance, improved engine cooling and serviceability.

- Maximize your equipment investment with services like Customer Value Agreements, Custom Track Service and genuine Cat Parts.

- Remanufactured parts offer a lower cost replacement option.

- Certified Rebuild gives a “second life” for your machine.

TECHNOLOGY THAT GETS WORK DONE

- Cat Grade technologies help operators of varying experience levels hit target grade faster and more accurately.

- Cat Slope Indicate displays real-time machine mainfall and cross-slope on the primary monitor.

- Cat Grade with Slope Assist™ automatically maintains blade position without a GPS signal and requires no additional hardware or software. (Single tilt only.)

- With Attachment Ready Option (ARO), your dozer comes from the factory ready for simple installation of the 3D grade control system of your choice.

- Product Link™ collects machine data that can be viewed online through web and mobile applications

- Access information anytime, anywhere with VisionLink® and use it to make informed decisions that boost productivity, lower costs, simplify maintenance, and improve security on your job site

- All Cat Grade systems are compatible with radios and base stations from Trimble, Topcon, and Leica.

- Already invested in a grade infrastructure? You can install grade systems from Trimble, Topcon, and Leica onto the machine.

EQUIPPED FOR THE JOB

When you have an especially tough job, equip your dozer with factory options for added protection and even better performance.

- Waste Handler/Landfill arrangement offers specialized guarding, striker bars and seals help protect the machine from impact and airborne/wrapping debris. Cooling is designed for high debris environments and easy cleanout. Specialized air handling features help deliver cleaner air to the machine. Landfill blades and center-hole track shoes help optimize your waste handler for the job.

- A variety of factory options, like specialized undercarriage, final drives and fluids/lubricants allow you to equip your dozer to work in extreme cold. An Arctic cab with dual pane glass, as well as optional heated suspension seat, offer greater operator comfort in frigid conditions.

- Outfit your dozer from the factory with options like sweeps, screens and added guarding to provide extra protection in harsh applications like Forestry and Land Clearing.

Ask your Cat dealer about the full range of options to equip your dozer just the way you need it to get the job done.

Documents & Brochures

Standard Equipment

Power Train

- Cat C15 diesel engine

- Air cleaner- precleaner with strata tube dust ejector

- Air-to-Air Aftercooler (ATAAC)

- Electric fuel priming pump

- Electronically controlled powershift transmission

- Four planet double-reduction planetary final drives

- Hydraulically driven reversing fan

- Precleaner

- Prescreener

- Torque divider

- Turbocharger

Operator Environment

- Cab - Integrated ROPS/FOPS operator station

- Cloth seat

- Adjustable armrest

- Retractable seatbelt 76 mm (3 in)

- Pilot hydraulics

- Single tilt

- System warning lamps

- Lunchbox storage

Technology Products

- Compatibility with radios and base stations from Trimble, Topcon, and Leica

- Capability to install 3D grade systems from Trimble, Topcon, and Leica

Hydraulics

- Independent steering and implement hydraulic pumps

- Load sensing hydraulics - lift and tilt

Undercarriage

- Standard gauge

- Sealed and lubricated track: 44 sections with two-piece master links

- Heavy Duty, Positive Pin Retention (PPR) Track

- 610 mm (24 in) Extreme Service track

- End track guiding guards

- Equalizer bar

- Hydraulic track adjusters

- Lifetime lubricated idlers

- Lifetime lubricated track rollers

- Replaceable sprocket rim segments

- No carrier rollers

Service and Maintenance

- SOS(sm) sampling ports

- Vandalism protection for fluid compartments and battery box

- Ground level service center with remote electrical disconnect, secondary shutdown switch and hour meter

- Cat exclusive power train and hydraulic oil filters with extended service intervals

- Standard lubricant

- Front pull device

Electrical

- Diagnostic connector

- Lights - 6

Starters, Batteries and Alternators

- 150 Amp alternator

- Ether starting aid

- 2 maintenance-free heavy duty 12V batteries (1400 CCA) (24V system)

- Auxiliary starting receptacle

- Heavy duty 24V starter

Guarding and Seals

- Hinged bottom guards

Additional Information

| C15 Cat® - موديل المحرك | Cat C15 |

|---|---|

| المحرك - القدرة - الصافية | 242 كيلووات ( 325 حصان ) |

| المحرك - صافي القدرة - ISO 9249/SAE J1349 | 242 كيلووات ( 325 حصان ) |

| المحرك - صافي القدرة - ISO 9249 (DIN) | 328 قدرة حصانية مترية ( 328 قدرة حصانية مترية ) |

| المحرك - الانبعاثات | معايير الانبعاثات البرازيلية MAR-1 ومعايير الانبعاثات الصينية لمحركات الطرق الوعرة من المرحلة III المكافئة لمعايير وكالة حماية البيئة (EPA) الأمريكية من المستوى 3/الاتحاد الأوروبي من المرحلة IIIA، أو معايير الانبعاثات الصينية لمحركات الطرق الوعرة من المرحلة II، المكافئة لمعايير وكالة حماية البيئة (EPA) الأمريكية من المستوى 2/الاتحاد الأوروبي من المرحلة II |

| المحرك - رقم التصنيع | 19B |

| المحرك - إمكانية استخدام الديزل الحيوي | حتى B100* |

| المحرك - ملاحظة (1) | قدرة المحرك عند 1900 دورة في الدقيقة. صافي القدرة المعلن هو القدرة المتوفرة عند الحدافة عندما يكون المحرك مزوَّدًا بمروحة على السرعة القصوى، ومنظف هواء، وكاتم صوت، ومولد تيار متردد. يتم اختبار القدرة المعلنة وفقًا للمعيار المحدد الساري وقت التصنيع. |

| محرك - ملاحظة (2) | *تتوافق محركات Cat مع أنواع وقود الديزل الحيوي** المتجددة والبديلة التالية التي تقلل غازات الاحتباس الحراري طوال العمر: ديزل حيوي (FAME) حتى B20 *** وأنواع وقود متجددة حتى 100% HVO وGTL.* راجع التوجيهات لضمان نجاح الاستخدام. يرجى الرجوع إلى وكيل Cat أو "توصيات سوائل ماكينات Caterpillar" (SEBU6250) للحصول على التفاصيل.*** يمكن استخدام B30 إذا لزم الأمر. استشر وكيل Cat لديك بشان استخدام مخاليط أعلى حتى B100. *** يمكن استخدام حتى B100 عند التجهيز بخطوط وقود اختيارية تتوافق مع B100. لمزيد من المعلومات، يرجى الرجوع إلى دليل التشغيل والصيانة (OMM). |

| الأوزان - الوزن أثناء التشغيل | 38834 كجم ( 85614 رطل ) |

| سعات إعادة التعبئة للخدمة - خزان الوقود | 600 l ( 158.3 جالون (أمريكي) ) |

| SU قياسي - الوزن أثناء التشغيل | 38834 كجم ( 85614 رطل ) |

| SU قياسي - الضغط الأرضي | 88.2 كيلو باسكال ( 12.8 رطل لكل بوصة مربعة ) |

| SU قياسي - عرض المداس القياسي | 610 مم ( 24 بوصة ) |

| SU قياسي - الشفرة | شبه عام |

| SU قياسي - سعة الشفرة | 10.3 m³ ( 13.4 yd³ ) |

| LGP - الوزن أثناء التشغيل | 37525 كجم ( 82728 رطل ) |

| LGP - الضغط الأرضي | 52.3 كيلو باسكال ( 7.6 رطل لكل بوصة مربعة ) |

| LGP - عرض النعل القياسي | 965 مم ( 38 بوصة ) |

| LGP - الشفرة | شبه عام |

| LGP - سعة الشفرة | 9.9 m³ ( 12.9 yd³ ) |

| الصحراء/تآكل مرتفع - الوزن أثناء التشغيل | 39153 كجم ( 86316 رطل ) |

| الصحراء/تآكل مرتفع - الضغط الأرضي | 88.2 كيلو باسكال ( 12.8 رطل لكل بوصة مربعة ) |

| الصحراء/تآكل مرتفع - عرض النعل القياسي | 610 مم ( 24 بوصة ) |

| الصحراء/تآكل مرتفع - الشفرة | شبه عام |

| الصحراء/تآكل مرتفع - سعة الشفرة | 10.3 m³ ( 13.4 yd³ ) |

| جهاز التعامل مع النفايات - الوزن أثناء التشغيل | 38621 كجم ( 85122 رطل ) |

| جهاز التعامل مع النفايات - الضغط الأرضي | 88.2 كيلو باسكال ( 12.8 رطل لكل بوصة مربعة ) |

| جهاز التعامل مع النفايات - عرض المداس القياسي | 610 مم ( 24 بوصة ) |

| جهاز التعامل مع النفايات - الشفرة | مدافن نفايات شبه عامة |

| جهاز التعامل مع النفايات - سعة الشفرة | 21.2 m³ ( 27.8 yd³ ) |

| جهاز التعامل مع النفايات LGP - الوزن أثناء التشغيل | 37312 كجم ( 82236 رطل ) |

| جهاز التعامل مع النفايات LGP - الضغط الأرضي | 52.3 كيلو باسكال ( 7.6 رطل لكل بوصة مربعة ) |

| جهاز التعامل مع النفايات LGP - عرض النعل القياسي | 965 مم ( 38 بوصة ) |

| جهاز التعامل مع النفايات LGP - الشفرة | مدافن نفايات شبه عامة |

| جهاز التعامل مع النفايات LGP - سعة الشفرة | 22.2 m³ ( 29 yd³ ) |

| Offering Type |