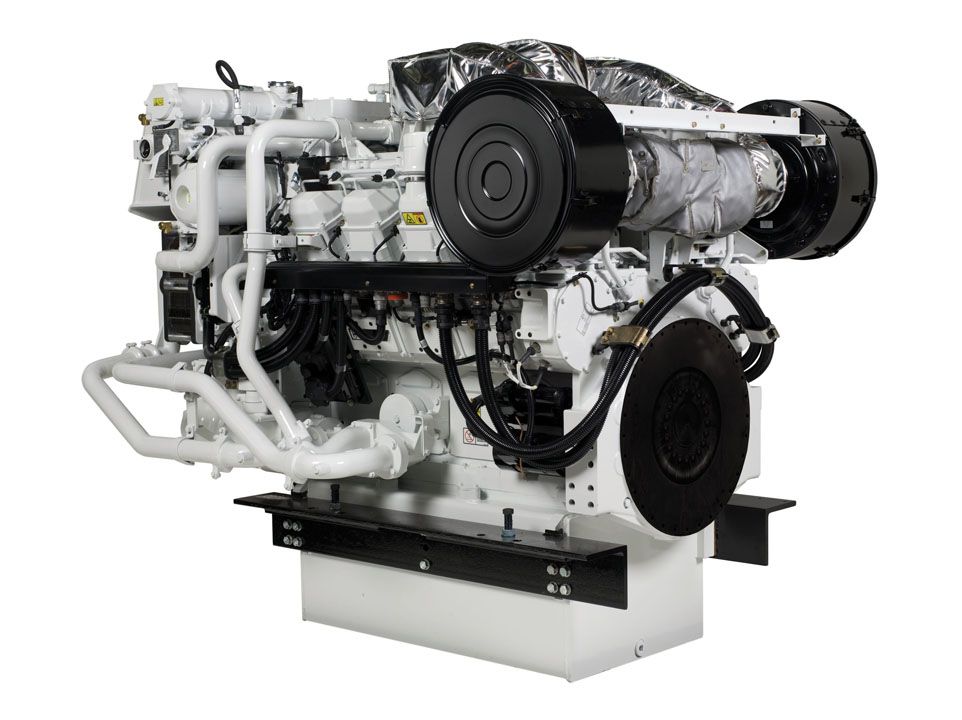

3508C

3508C Propulsion Engine

The 3508C marine propulsion engine meets IMO II emissions regulation and delivers more power with lower emissions for your marine propulsion needs. Additionally, the 3508C provides outstanding fuel efficiency and lube oil consumption. Standard or reverse rotation options are available as well as worldwide parts and service. The 3500 engine platform is a streamlined and proven design that provides industry-leading reliability & durability.

A3 Electronic Control Unit (ECU)

• One of the most advanced electronic control systems available for Cat marine engines. • Faster with more memory capability than ADEM 2 • Compatible with several optional display systems • Does not require fuel cooling • Enhanced input/output capacity • Rugged marine design and IP66 connectors • Award-winning circuitry design

Engine-Mounted Instrument Panel

• Integrated MPD display for quick response and effective local control • Optional local speed control • Optional individual cylinder exhaust temperature scanner with data link for remote mounting • Local E-stop, warning indicators, horn • Plug & Run connections allow mounting on port or starboard side of engine

Marine Power Display (MPD)

• Graphic display of engine operating parameters in analog, digital, or bar-chart format • Rugged weatherproof construction • Fully user-configured display screens • Marine classification society-type approved • Diagnostic messages and alarms • Three-tier prioritization of events and diagnostics • Multilingual capability • Night-mode LCD display • ISO symbols for parameter identification

High Capacity High Efficiency Turbos

• Standard marine twin turbocharger configuration. • More reserved power for superior part load performance at continuous ratings • Turbos tuned for high power and excellent fuel consumption

Engine-Mounted Cat® Plate-Type Heat Exchanger

• Separate Circuit Aftercooled (SCAC) • Single heat exchanger for both jacket water and aftercooler systems • Single inlet and outlet connections for sea water • Lightweight and compact • Factory-installed piping and connections

Rigid Wiring Harness

• Highly durable: long service life • Flexibility for custom wire additions • Lined with fire retardant foam • Cost efficient replacement for premium wiring • Marine classification society approved

Power Distribution Box

• Isolates “control power” from alternator/starter/jacket water heater power • Mountable off engine • Allows end user to choose up to three independent power sources • Has built-in circuit breakers and switches for easy troubleshooting

Marine Classification Society Approvals

• ABS/DNV/LR/GL/CCS/BV/RINA

Electronic Features

• 3D histogram data of engine operation (load, speed, time) • Load feedback signal for CPP operation • Electronic torque limit for re-power and torque limited application equipment • Programmable droop • Adjustable governor gains • Condition-based maintenance • Monitoring features • Serial data bus communications • Primary and secondary A3 controllers on all propulsion engines

Cat Pilot House Panels

• Cat pilot house panels with or without Marine Power Display (MPD) • Easily connected to the engine customer connector • Ability to have full function helm panels and reduced function wing panels

Unit Injectors

• Caterpillar designed and built system • “Drop-in” installation • No threaded fuel connections • High pressure only inside injector does not require double wall lines or leak collection devices

Power Take-off

• Power take-off adapters available • Auxiliary drives for power take-offs for hydraulic pumps and compressors

Engine-Mounted Gear-Driven Pumps

• Standard engine-mounted aftercooler pump • Standard engine-mounted jacket water pump • Optional engine-mounted, gear-driven, high capacity sea water pump

Engine Mounting System

• Rigid mounting points • Optional resilient mounting

In-Hull Overhaul

• Easily removable side covers • Accessible bearing caps

Documents & Brochures

Standard Equipment

Fuel System

- Fuel filter, RH, with service indicators.

- Fuel transfer pump.

- Electronically controlled init injectors

Instrumentation

- Graphical Unit (Marine Power Display) for analog or digital display of

Lube System

- Crankcase breather, Top mounted

- Oil filter, RH, with service indicators

- Oil filler and dipstick, RH

- Standard sump oil pan (500 Hour oil change interval)

- Oil pump, gear type

Mounting System

- Rails, engine mounting, ledge type, 203 mm x 203 mm (8 in x 8 in)

Power Takeoffs

- Accessory drive

- Front housing, two-sided

Protection System

- A4 ECU Electronic Monitoring System provides customer programmable engine de-rate strategies to protect against adverse operating conditions

- AIII Electronic Monitoring System provides customer programmable engine de-ration strategies to protect against adverse operating conditions

- Emergency stop push button (located in Electronic Instrument Panel) Safety shutoff protection:

General

- Vibration damper and guard

- Lifting eyes

- Paint, Caterpillar Yellow engine with black rails

- NOTE: Engines for heat exchanger cooling do NOT include heat exchanger.

Flywheel and Flywheel Housing

- Flywheel, SAE No. 0, 151 teeth.

- Flywheel housing, SAE No. 0.

Air Inlet System

- Separate circuit aftercooler core, corrosion resistant coated (air side)

- Air cleaner, regular duty

- Dual turbochargers, 152 mm (6 in) OD straight connection

Control System

- Dual Caterpillar A-III Electronic Engine Control, LH with Electronic Unit Injector Fuel System

- Rigid Wiring Harness (10 amp DC power required to drive Electronic Engine Control Module)

Cooling System

- Oil cooler

- Thermostats and housing, Full open temperature 92 C (198 F)

- Jacket water pump, gear driven, centrifugal

- Auxiliary fresh water pump with SCAC engines

- Auxiliary sea water pump, Centrifugal, Non-self-priming

- Expansion tank

Exhaust System

- Dry gas tight exhaust manifolds with heat shields.

- Dual turbochargers with watercooled bearings and heat shield.

- Exhaust outlet, vertical, 203 mm (8 in) round flanged.

Additional Information

| تقدير القدرة - نطاق القدرة | 775-1100 قدرة حصانية للفرامل (578-820 كيلووات للفرامل) |

|---|---|

| مواصفات المحرك - نطاق السرعة | 1200-1600 دورة في الدقيقة |

| مواصفات المحرك - الانبعاثات | IMO II، EU IW |

| مواصفات المحرك - السحب | TTA |

| مواصفات المحرك - التجويف | 170.0 مم ( 6.7 بوصة ) |

| مواصفات المحرك - الشوط | 190.0 مم ( 7.5 بوصة ) |

| مواصفات المحرك - الإزاحة | 34.5 l ( 2107.0 بوصة³ ) |

| مواصفات المحرك - الدوران من طرف الحدافة | عكس اتجاه عقارب الساعة أو في اتجاه عقارب الساعة |

| مواصفات المحرك - التكوين | ديزل على شكل حرف V ذو 8 أسطوانات، دورة رباعية الأشواط |

| الأبعاد والأوزان - أدنى وزن جاف | 4960.0 كجم ( 10935.0 رطل ) |

| الأبعاد والأوزان - الطول | 2117.0 مم ( 83.4 بوصة ) |

| الأبعاد والأوزان - الارتفاع | 1829.0 مم ( 72.0 بوصة ) |

| الأبعاد والأوزان - العرض | 1703.0 مم ( 67.0 بوصة ) |

| Offering Type |